Split faced blocks are increasingly sought after for their distinctive textured appearance. Their iconic aesthetic adds depth and character, offering a unique alternative to traditional facing bricks for those looking to achieve a more defined masonry style.

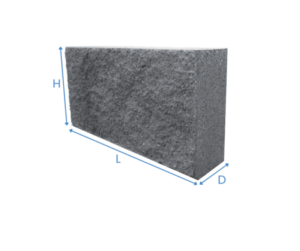

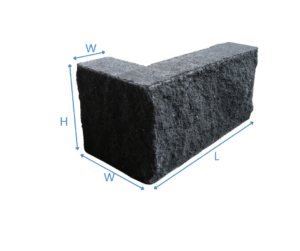

| Length | Height | Width | Weight Per Unit | |

|---|---|---|---|---|

| Split Face - 9X4 | 440 | 215 | 100 | 19kg |

| Split Face External L Corner | 440 | 215 | 215/100 |

Fire Resistance

Barrett’s Split Face blocks are fire rated as Class A1, in accordance with BS EN 13501- 1:2007 + A1:2009.

The textured finish adds detail and dimension, creating a striking and timeless look. Known for their high density, split faced blocks provide superior durability, making them suitable for demanding applications.

| Tolerance Category | D1 |

| Manufactured to | BS EN 771-3 |

| Grouping according to EN 1996 1-1 | Group 1 |

| Means Comprehensive Strength | 10.5 N/mm² |

| Reaction to Fire | A1 |

| Water Absorption | 8.64 g/m2s |

| Water Vapour Permeability | 5/15μ |

| Direct Airborne Sound Insulation -Gross density | 2030 kg/m³ |

| Thermal Resistance | (P=50) 0.90 W/(mK) (P=90) 1.09 W/(mK) |

| Durability against freeze thaw | Refer to requirements in table 15- PD 6697:2019Aggregate in accordance withEN 12620 and S.R. 16:2016 |